A Grok-generated photo montage.

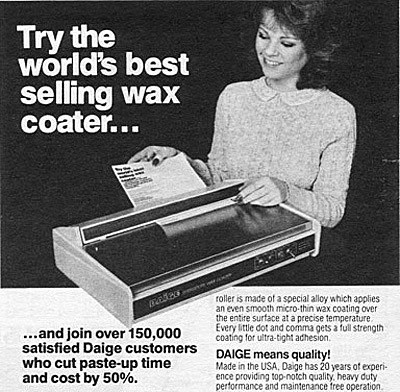

In the old-school design studios, various hazards lurked (like Bestine, X-acto knives, and harsh chemicals from the stat room, not to mention the tension with the camera operators). However, the waxer stood out as a relatively benign tool. It wasn’t poisonous, its fumes had a sort of agreeable, beeswax aroma, and it performed its task efficiently.

Throughout much of the 20th century, the tools of the trade for graphic designers and publishers were simple yet essential: the waxer, the non-repro blue pencil, and the paste-up board. These were the foundational elements that facilitated the mass communication boom, from high school yearbooks to major national advertising campaigns. Newspapers, magazines, and the ads within them were meticulously crafted using this method, with an enormous amount of wax being heated and applied worldwide.

In the mid-1970s, the graphic arts industry was on the cusp of a technological renaissance. The revolution in the typesetting industry marked a significant shift from traditional galley output to digital page layout systems, fundamentally changing how printed material was prepared for publication. This transformation began with the advent of desktop publishing (DTP), spearheaded by innovations like Adobe’s PageMaker in 1985 and later, Adobe InDesign. These tools allowed designers and publishers to create, edit, and layout text and images directly on a computer screen, replacing the labor-intensive process of physical galleys, hot metal typesetting, and the intricate hand-assembly of type blocks. The digital workflow not only sped up the production process but also allowed for immediate visualization and manipulation of layouts, reducing errors and material waste. Moreover, this shift to digital facilitated direct output to film for platemaking in offset printing, bypassing many intermediate steps in traditional typesetting. This revolution not only democratized publishing by making sophisticated layout tools accessible to smaller operations and individual designers but also significantly lowered the barrier to entry in terms of cost and complexity, thereby reshaping the publishing landscape into the digital age.. Here’s how it worked:

Traditional Color Separation (1975 and Earlier)

Creating full-color prints in the era before digital technology was a sophisticated and labor-intensive process, heavily reliant on mechanical precision and human skill. The heart of this process was the large process camera, an imposing piece of equipment that dominated the prepress rooms of print shops. Here’s a detailed look at how color separation unfolded:

The Initial Setup: An original full-color, continuous-tone image—usually a photograph or specially crafted artwork—was carefully positioned on a flat copyboard inside a process camera. This camera, essentially a magnified version of a traditional photographic camera, was tailored for detailed macro photography, offering meticulous control over light exposure.

The Filtration Process: The room was darkened to control light exposure, and the photographer began by setting up the camera to expose through a series of precise optical filters: red, green, and blue (RGB). Each filter was meant to isolate one of the primary colors by blocking the light of the other two.

Red Filter: Used to capture the cyan separation, as red light is absorbed by cyan ink.

Green Filter: For the magenta separation, since green light is absorbed by magenta.

Blue Filter: For the yellow separation, blue light is absorbed by yellow ink.

Exposing the Film: For each filter, the image was exposed to high-contrast, orthochromatic film which responded to light in a way that created stark contrasts, essential for the separation process. Each exposure produced a film negative that represented one of the subtractive color primaries: cyan, magenta, and yellow. A fourth exposure, usually without a filter or using a specific black filter, was made for the key plate or black.

Alignment and Precision: The films had to be perfectly aligned, as any misalignment would result in color shifts or ghosting in the final print. This required meticulous attention to detail, often involving the use of pin registration systems where tiny holes punched in the films ensured perfect alignment across all four films.

Developing and Checking: Each film was developed in a darkroom, and the separations were carefully inspected for any errors or imperfections. Adjustments might be made, such as dot etching to manually adjust color balance or density by physically altering the dots on the film.

Creating Printing Plates: Once the films were approved, they were used to create printing plates. This could be done through various methods like photopolymer plates or metal etching, where the film’s image was transferred onto a plate, one for each color. Each plate would then be fitted onto a printing press, allowing ink of the corresponding color to be applied to the paper in perfect registration with the others.

This process demanded not just technical expertise but also an artistic eye to ensure that the final printed piece accurately represented the original artwork. The transition from this analog method to digital processes marked a significant leap in the graphic arts, simplifying many steps while also introducing new challenges and possibilities in color reproduction

The Art of Film Stripping in Color Separation

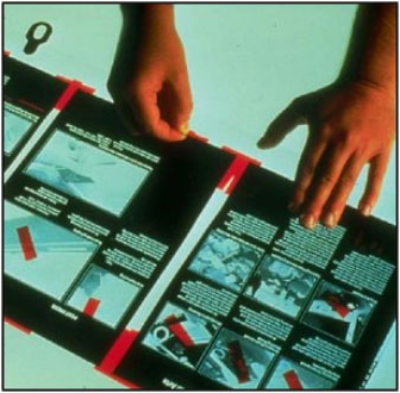

In the early days of color printing, before digital technology took over, the process of “film stripping” was a critical step in producing color-separated images for printing. Here’s a glimpse into this meticulous craft:

The Basics: After capturing the color separations using large process cameras with colored filters, the resulting films (often negatives) for each color (cyan, magenta, yellow, and black) had to be precisely aligned to form the complete image. Here is how the process worked:

Alignment: Each film was inspected for quality and then aligned using pin registration systems. These systems ensured that every piece of film for the different colors lined up perfectly, vital for avoiding color misregistration in the final print.

Stripping: This involved the physical pasting of these films onto a larger, clear base sheet. Using a light table, operators would carefully cut out the image areas from each film and then “strip” them onto a goldenrod (yellow) or orange masking paper. This background color helped in making sure no part of the film was accidentally exposed during the plate-making process.

Tape and Tools: Special tapes, opaque to UV light but transparent to visible light, were used to secure these films. The tools of the trade included exacto knives, loupes for magnifying, and alignment tools.

Dot Etching: Sometimes, color adjustments were made by manually etching away or adding to the halftone dots on the film with a pointed tool or acid. This technique allowed for fine-tuning color balance before the film was used to make plates.

The Art in the Craft: Film stripping was not just a technical task but an art form. It required a deep understanding of how light and ink would interact on paper, making the stripper not just a technician but a craftsman.

The film stripping process was the bridge between photographic and printing technologies, a testament to the precision and artistry involved in producing full-color printed materials before digital workflows became the norm. Today, while the digital age has largely replaced this method, the legacy of film stripping endures in the print industry’s appreciation for high-quality, accurate color reproduction.

Magnascan color scanner for the printing industry, designed and made by Crosfield Electronics Ltd., winner of a Design Council Award for Engineering Products in 1978.

Transition to Electronic Prepress (Late 1970s – Early 1980s)

The late 1970s and early 1980s witnessed a monumental shift in the graphic arts industry with the advent of high-end color electronic prepress systems, with Scitex emerging as a pioneer in this transformation. Here’s a detailed look at how this transition revolutionized the prepress workflow:

The inception of Digital Prepress: The introduction of digital prepress systems by companies like Scitex from Israel marked a pivotal moment in the graphic arts industry. These systems were pioneering in fully digitizing the color separation process, signaling the decline of traditional darkroom techniques. Rather than manually photographing images through color filters, these systems utilized high-resolution drum scanners for capturing images.

Simultaneously, the advent of Crosfield’s digital color separation equipment further propelled this transition. This technology shifted the industry from analog photographic methods to digital workflows, significantly enhancing the efficiency of color print production.

The adoption of digital color separation equipment was not merely an upgrade in technology; it acted as a catalyst for the widespread integration of digital solutions in print production. This shift laid the groundwork for contemporary graphic design and printing, where precision, speed, and customization are now standard, fundamentally transforming the field of visual communication.

The Scanning Process: These scanners captured images by spinning them on a drum while a laser or photodetector scanned across them, converting the visual information into digital data. This data represented not just the visual information but also the color separation components directly in the digital realm.

Digital Color Separation: Within the system’s computer, sophisticated algorithms separated the image into its CMYK components. This was a significant leap; now, instead of physical films, operators worked with digital files. This allowed for:

Enhanced Precision: Digital systems could achieve a level of accuracy in color separation that was beyond the capabilities of manual methods.

Color Manipulation: Operators could adjust color balance, saturation, and other attributes in real-time, using digital tools to achieve results that were either impossible or extremely cumbersome with traditional techniques.

Proofing: Digital prepress systems allowed for the creation of color proofs directly from the digital files, providing a more accurate preview of the final print before actual press production.

Outputting to Film: One of the standout features of systems like Scitex was their ability to output directly to film. Using a high-resolution laser film writer, these systems could produce film negatives or positives for each CMYK color directly from the digital files. This bypassed the need for intermediate steps like creating and developing films from camera exposures, significantly reducing both time and potential for error.

Integration with Printing Workflows: These systems were integrated into the printing workflow, often requiring specialized training for operators. However, the benefits were substantial: reduced production times, lower material costs due to less waste, and the ability to make on-the-fly corrections without re-shooting entire sets of separations.

Economic and Industry Impact: While initially very expensive, limiting their use to major commercial printers or large publishing houses, these systems set the stage for future developments in desktop publishing. The high cost was offset by the efficiency gains, leading to a ripple effect where smaller print shops eventually demanded similar, albeit less costly, technology.

This era marked not just a technological advancement but a paradigm shift in how the printing industry approached color reproduction. It laid the groundwork for what would become the digital publishing revolution, where precision, flexibility, and speed became the new standards.

The Desktop Publishing Revolution (Mid-1980s onwards)

The mid-1980s ushered in a new age for graphic design with desktop publishing, a revolution catalyzed by both innovative software and the introduction of the Macintosh computer, fundamentally changing how designs were created and printed.:

Inception of Desktop Publishing: The release of Adobe PageMaker in 1985 and QuarkXPress in 1987 marked the beginning of this revolution. These applications brought professional layout and design capabilities to personal computers, significantly democratizing the prepress process.

Adobe PageMaker and QuarkXPress: These programs allowed users to design and layout pages with text, graphics, and images on standard computers. They were intuitive enough for wide adoption yet powerful enough to challenge the specialized systems of the time.

Integration with PostScript: Central to this revolution was PostScript, Adobe’s page description language. PostScript acted as a bridge, translating the digital layout into instructions that could be understood by output devices. This was crucial for maintaining the integrity of designs from screen to print.

Advances in Printing Technology: Concurrent developments in laser printing technology meant that personal computer users could now produce hard copies of their designs directly from their machines, albeit at lower resolutions than what professional print shops achieved.

Desktop Color Separation

The ability to perform color separation at the desktop transformed the workflow:

Digital Workflow: Designers could now integrate full-color images into their layouts directly within their software. Tools within PageMaker and QuarkXPress allowed for basic color adjustments and separations, though more complex work required dedicated color management software.

Cost and Accessibility: This shift drastically reduced the cost barrier associated with color printing. Previously, small businesses or individual designers had to rely on external services for color separations, which were both time-consuming and expensive.

Departure from High-End Systems: While systems like Scitex offered superior color management, desktop solutions were good enough for many applications, especially with the rise of color management systems that improved the accuracy of on-screen color representation.

PostScript and Imagesetters

PostScript played a pivotal role in bridging the gap between digital design and high-quality print:

Imagesetters: These were devices capable of producing film or plates at resolutions much higher than standard laser printers. PostScript allowed software to communicate with these devices, creating incredibly detailed separations or direct-to-plate images.

From Screen to Print: The phrase “What You See Is What You Get” (WYSIWYG) became more of a reality, though it still required calibration and understanding of the differences between monitor display and print output.

Impact on the Industry: This technology meant that smaller print shops or even individuals could produce professional-quality print materials without the need for large, expensive prepress systems. It also accelerated the pace of production, as revisions could be made quickly on the computer rather than through multiple physical cycles of film development.

The combination of desktop publishing software, PostScript, and imagesetters not only democratized graphic design but also shifted the power of production closer to the hands of creatives, sparking an era of experimentation and innovation in printed media. This period laid the groundwork for the digital design tools we take for granted today, where color management and high-resolution output are standard features on even consumer-grade equipment.

The evolution from darkroom color separation to digital desktop systems not only democratized the printing process but also dramatically sped it up. While the quality and complexity of color work available at the desktop level initially lagged behind high-end prepress systems, the gap closed rapidly with technological advancements. Today, we take for granted the ability to produce high-quality color prints from our desktop computers, but it’s worth reflecting on the journey from those darkrooms of the ’70s to the digital desks of today.

AI Imaging: The Next Frontier in Design and Printing

Enter AI imaging, which promises to revolutionize how we approach design and printing with its ability to generate high-quality, personalized visuals at scale. This not only enhances the customization potential of digital printing but also introduces new creative possibilities, potentially bridging the gap between digital convenience and the tactile allure of print, while redefining industry standards for speed and innovation.

AI imaging’s integration into the graphic design industry marks a pivotal shift, offering designers tools to enhance productivity and creativity. These tools, as discussed in various platforms including X, enable rapid design iterations and personalized content at scale, which could democratize design but also raises concerns about job displacement for traditional graphic designers. While AI’s ability to generate high-quality visuals quickly might streamline processes, it also challenges the industry with issues of originality, environmental impact due to high computing demands, and the potential for a homogenized aesthetic over time. This duality suggests a future where AI and human creativity must coexist, with AI serving as an augmentative rather than a replacement technology, fostering a new creative landscape that values both efficiency and the unique human touch in design.

Reflecting on the journey from darkroom color separations to AI-generated visuals, we celebrate the relentless ingenuity of graphic arts professionals. These pioneers not only adapted to but also drove the technological shifts that have redefined the frontiers of print and visual communication. This evolution underscores a vibrant future where the synthesis of human creativity with AI’s capabilities promises to further transform how we design, print, and perceive visual narratives, marking an ongoing chapter in the dynamic saga of graphic design and printing.

This blog post is inspired by my friend Claudia McCue, a work associate from the 1970s. Claudia was a consummate professional in the graphic arts industry, known for her early adoption and mastery of the technologies discussed herein. Her forward-thinking approach and dedication to her craft have been a guiding light, illustrating the profound impact of technological innovation on visual communication. This post celebrates her legacy and the broader evolution our industry has undergone.

This blog post is inspired by my friend Claudia McCue, a work associate from the 1970s. Claudia was a consummate professional in the graphic arts industry, known for her early adoption and mastery of the technologies discussed herein. Her forward-thinking approach and dedication to her craft have been a guiding light, illustrating the profound impact of technological innovation on visual communication. This post celebrates her legacy and the broader evolution our industry has undergone.

Claudia, with over three decades in commercial printing followed by two decades as a software trainer specializing in Adobe’s suite—InDesign, Illustrator, Photoshop, and Acrobat—has recently transitioned into a firearms instructor. Her focus … guiding new female shooters towards comfort and safety with firearms. This new role mirrors her previous career in teaching software, as both involve navigating individuals through unfamiliar territories with empathetic guidance. Reflecting on her experience, Claudia shares on LinkedIn, “It’s great to see the shoulders relax, and the big grin appear after they’ve fired the first shot!”

I am profoundly grateful for my dear friend Claudia. Her unwavering friendship shared laughter, and companionship over the years have been a continuous wellspring of support and inspiration, for which I am deeply thankful.