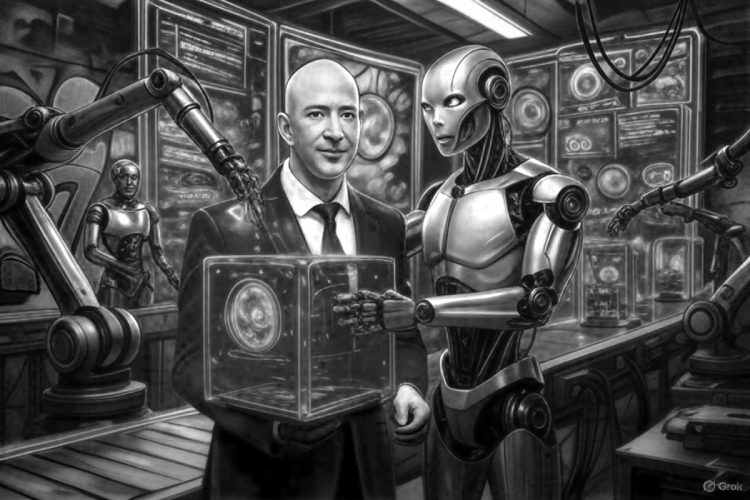

A vision of what Project Prometheus might become by 2035.

In a stark-white laboratory somewhere in the American Southwest, thousands of robotic arms work in synchronized ballet, mixing exotic compounds and testing materials at a pace no human team could match. This is the vision Jeff Bezos has placed a $6.2 billion bet on—and by 2035, Project Prometheus may have fundamentally altered how humanity designs and produces everything from computer chips to spacecraft.

The Foundation: Physical AI Meets Autonomous Discovery

Project Prometheus emerged in late 2025 as a stealth powerhouse, co-led by Bezos and serial moonshot architect Vik Bajaj, who previously incubated Google’s Wing drones and Waymo self-driving technology. The company’s early acquisition of General Agents—an AI startup building autonomous computer-control systems—revealed its core strategy: creating AI that doesn’t just think, but acts in the physical world. By 2035, this “physical AI” approach will likely have matured into something far more ambitious than today’s factory automation.

The company’s partnership model with Periodic Labs offers crucial insight into its trajectory. Periodic’s autonomous laboratories use AI to conduct thousands of materials science experiments daily, learning from real-world physics rather than internet text. A decade from now, Project Prometheus will likely operate dozens of such facilities globally, each one a self-improving research engine discovering novel alloys, semiconductors, and composite materials that human scientists never imagined. The company’s focus on superconductors and advanced materials suggests that by 2035, it could hold patents on room-temperature superconducting materials that revolutionize power transmission and quantum computing.

Vertical Integration: From Atomic Design to Assembly Line

What distinguishes Bezos’ vision from typical AI companies is vertical integration at a scale that would make even Amazon look modest. By 2035, Project Prometheus won’t just design materials—it will engineer the robots that manufacture them, program the AI agents that optimize production, and potentially even operate the factories themselves. The company’s current focus on computers, aerospace, and automotive manufacturing provides the blueprint.

Imagine semiconductor fabrication plants where AI scientists continuously redesign chip architectures based on real-time performance data from autonomous testing labs. Picture automotive assembly lines where humanoid robots—themselves designed and built by Project Prometheus systems—adapt manufacturing processes on the fly as new materials emerge from the company’s research pipeline. Bezos’ significant investment in Physical Intelligence, a robotics AI startup, hints that by 2035, the company could be manufacturing its own line of general-purpose humanoid workers optimized for complex industrial tasks.

The aerospace connection runs deepest. With Bezos’ Blue Origin pursuing lunar industrialization, Project Prometheus appears positioned to become the R&D engine for off-world manufacturing. A decade hence, the company may operate the first materials science laboratory on the Moon, using AI-directed robots to test lunar regolith as construction material and extract rare elements in the vacuum of space—work far too dangerous and expensive for human scientists.

The Data Moat: Nature as Training Ground

Traditional AI companies face a looming crisis: they’re running out of internet data to train on. Project Prometheus has solved this by making nature itself the training environment. Each autonomous experiment generates gigabytes of high-quality, proprietary data. By 2035, the company will likely possess the world’s largest materials science dataset—billions of experiments across chemistry, physics, and engineering domains. This “data moat” creates nearly insurmountable competitive advantages.

The company’s talent acquisition strategy—pulling researchers from OpenAI, DeepMind, Meta, and Nvidia—suggests it’s building foundation models specifically trained on physical-world interactions rather than language. A decade from now, these “physics foundation models” could predict material properties, manufacturing defects, and engineering solutions with superhuman accuracy. Industrial partners will license access to these models, creating a recurring revenue stream that dwarfs today’s cloud computing markets.

The Competitive Landscape and Existential Questions

By 2035, Project Prometheus may face formidable competition from unexpected directions. China’s state-directed AI initiatives could create parallel autonomous research infrastructure, triggering a materials science arms race with geopolitical implications. Traditional manufacturing giants like Siemens, General Electric, and Toyota might form defensive consortiums, pooling research to counter Bezos’ integrated approach. Tesla, with its vertical integration philosophy and Optimus humanoid program, represents perhaps the most direct competitor, though focused more narrowly on automotive and energy applications.

More fundamentally, a Project Prometheus success raises uncomfortable questions about human scientific enterprise. If AI systems can discover breakthrough materials thousands of times faster than human researchers, what happens to materials science as a profession? The company’s trajectory suggests a future where human scientists become “prompt engineers” for autonomous labs—setting high-level research goals while AI handles experimentation and discovery. Universities may struggle to justify traditional PhD programs when AI can compress decades of research into months.

The economic implications ripple outward dramatically. American manufacturing could experience a genuine renaissance if Project Prometheus delivers on its promise—but the jobs created may require technical sophistication far beyond today’s workforce. Bezos’ company might pioneer the first fully “lights-out” factories that operate for months without human intervention, designed and optimized entirely by artificial intelligence.

The 2035 Snapshot

Ten years hence, Project Prometheus likely operates as something between ASML—the semiconductor equipment monopolist—and Bell Labs at its innovative zenith. The company may manufacture the robots that build advanced chips, the materials that enable next-generation batteries, and the AI systems that design spacecraft for lunar mining operations. Its market capitalization could rival or exceed the companies that Bezos and Bajaj previously built, justified by both revolutionary technology and irreplaceable data advantages.

Yet for all its potential, Project Prometheus represents a peculiarly Bezos-flavored bet: long-term thinking, vertical integration, and tolerance for massive upfront investment before profitability. Whether that bet pays off depends on variables even AI cannot fully predict—regulatory responses to autonomous research, breakthrough pace, and whether competitors can mobilize resources to challenge his head start. But if history suggests anything, it’s that betting against Jeff Bezos’ ability to build transformative infrastructure at scale has been a consistently losing proposition.

The 2035 factory floor may look nothing like today’s—and Project Prometheus intends to design, build, and operate the future that replaces it.

The name Prometheus—the Titan who stole fire from the gods and gave it to humanity—feels more apt with each passing year. Like its mythological namesake, the company has brought transformative power within human reach. Whether that power proves to be enlightenment or conflagration remains the defining question.

Standing on the factory observation deck, watching robots assemble components destined for Mars while AI agents redesign the production line in real-time, one sees the future Bezos imagined. It is efficient, ambitious, and slightly alien—a world where the boundary between tool and intelligence has dissolved, where manufacturing has become a form of continuous creation rather than repetitive production.

The fire has been delivered. What humanity builds with it will define the next century.